ESG

For all organisations, the need to lower energy consumption and reduce their carbon footprint has shifted from ‘nice to have’ to business imperative – for profits and the planet.

These ESG initiatives address a broad church of issues, from changing the procurement requirements demanded of suppliers to transitioning vehicle fleets to EVs.

However, one of the heaviest uses of carbon – that often goes overlooked – resides in the mechanical HVAC systems found in offices, hospitals, universities and many retail environments.

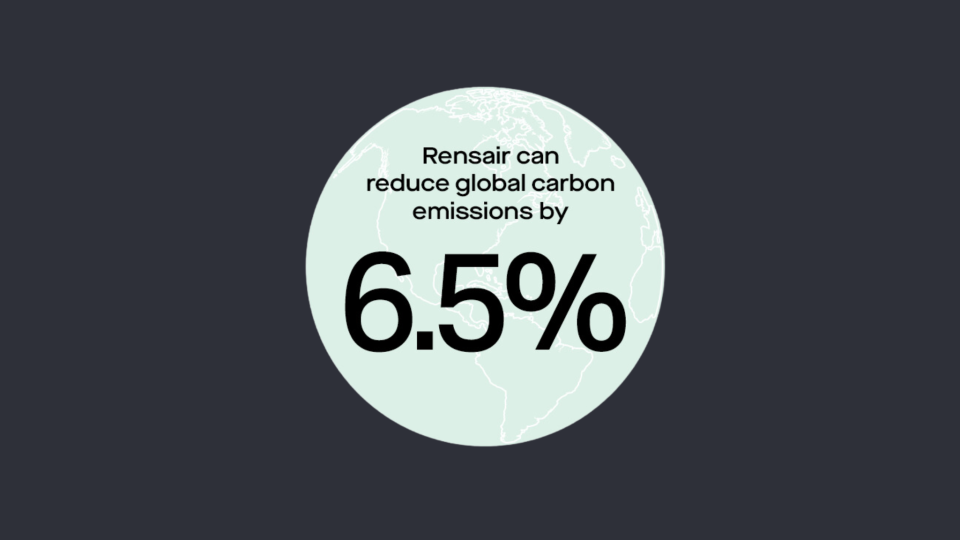

Carbon emissions reduction

Together, we can reduce global carbon emissions by 6.5%

The more space an organisation occupies, the greater its need for HVAC, leading to higher bills and a bigger carbon footprint. It’s an incredibly difficult problem, one that traditional ventilation systems were never designed to solve.

That’s why Rensair has developed best-in-class hardware and software to hack HVAC and improve the energy efficiency of these indoor spaces, radically lowering carbon output.

Our extensive research on emission levels and space optimisation proves we can decarbonise organisations’ real estate, and make a big difference to the planet.

Clean air and a better quality of life.

Nine out of ten people breathe air with pollutant levels that exceed the WHO’s guideline limits, creating adverse impacts on the six body systems: brain; nervous; cardiovascular; respiratory; endocrine; and renal. It’s a truly global healthcare risk and it needs urgent fixing.

Polluted air has been linked to many serious health risks, including neurological disorders, Alzheimer’s, cancer, and diseases of the heart, lungs and kidneys. Indoor air is recorded to be up to five times worse than the air outside. The WHO estimates that reducing annual average fine particulate matter (PM2.5) concentrations from 35 μg/m3 to 10 μg/m3 could reduce air pollution-related deaths by around 15%

We’ve designed our technology with a clear goal in mind: to protect and enhance lives by providing clean air in every indoor space, leading to higher performance, improved productivity and heightened cognitive functions, all of which contribute to a better life.

Our ESG Goals

At Rensair, we believe that we must earn our social licence to operate. As experts in clean air and indoor air quality, it follows that we feel strongly about pollution and taking affirmative action to clear the air.

Within our own business, this means practising what we preach. We are transparent in how and where we deliver our product from design to manufacture, you can read more below:

Charity

At Rensair we strive to be a force for good in everything we do. In addition to providing clean air for all, we actively support charitable causes, disadvantaged groups, community programmes and sustainability initiatives wherever we can.

We also recognise that many charities are under more pressure and a higher need than ever, with the cost of living rising rapidly in many areas, to global challenges increasing utility costs worldwide, so any organisation with official charitable status will automatically qualify for heavily discounted pricing on our technology, proportional to the number of units required. Even if your budget is stretched to the limit, please get in touch and we will do whatever we can to help.

Examples of charities that have benefited from Rensair air purification include the Red Cross, Citizens Advice Bureau, Ronald McDonald House Charities, Muscular Dystrophy Support Centre, Shrewsbury Food Hub, SSAFA, and Kirrie Connections.

Talk to us about your charity, and let’s work together to clear the air and lower your energy costs

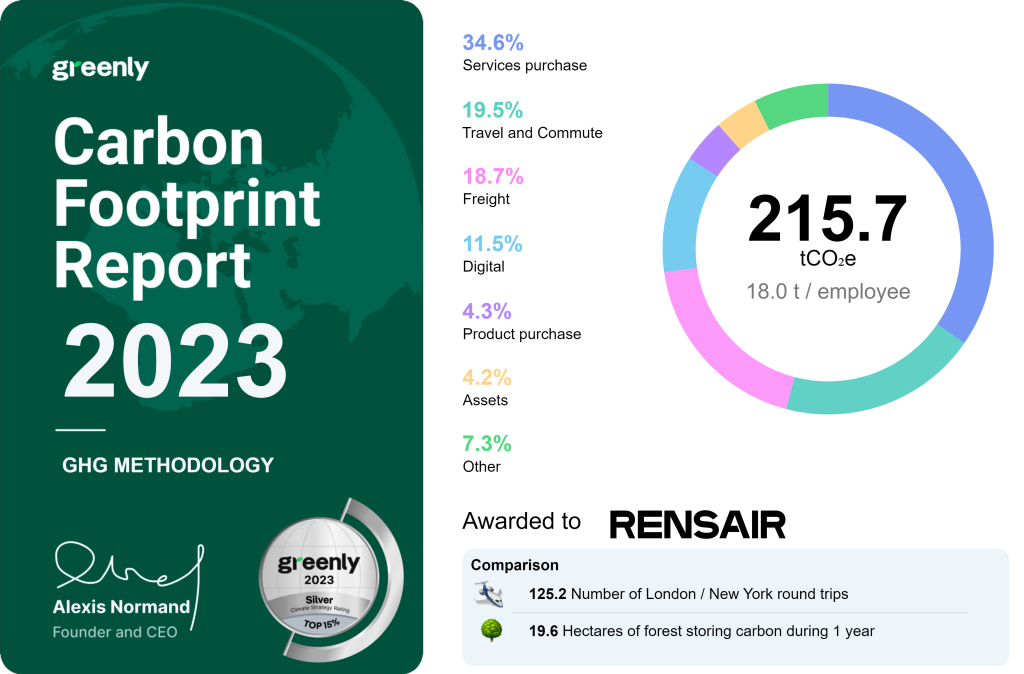

Carbon footprint

Minimising our own carbon footprint

From our manufacturing site, our products are transported to stocking & distribution centres in the UK, Europe and the USA. Having conducted a materiality assessment, sea freight is the least damaging form of freight forwarding, but it represents a significant proportion of our overall carbon footprint. That’s why we have opted into a carbon offset programme, taking positive action to limit our climate impact and hasten the transition to a clean energy future.

Via our logistics partners, Flexport, we contribute $6.50 per tonne of carbon emitted to Carbonfund.org in order to fully offset our carbon footprint. That money goes towards the Russas-Valparaiso Projects in the Amazon rainforest of western Brazil. Protecting 70,000 hectares of tropical rainforest, the goal is to mitigate the release of approximately 3 million tonnes of carbon dioxide emissions.

Eutraco, our distribution partner in Antwerp, Belgium, received the TransportMedia logistics building of the year award 2021. The facility is the very first carbon and energy neutral warehouse put into service by a 3PL logistics solutions provider.

Energy

Energy Use

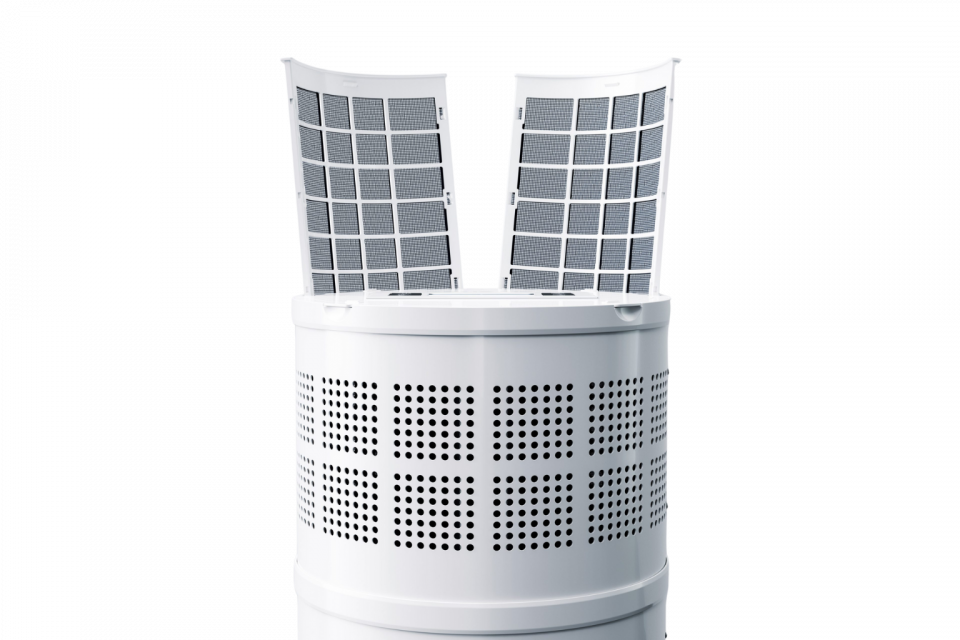

Rensair units use only 160 – 220W of power, depending on the airflow level. This is equivalent to a modern fridge-freezer found in most residential kitchens.

Using Rensair can significantly reduce energy costs for business premises. In cold climates, any intake of outdoor air must be heated. Since Rensair air purifiers are so effective at cleaning the air, the intake of fresh, outdoor air can be reduced, thereby saving on ventilation and heating bills. Similarly, in hot climates, less fresh air means less energy on ventilation and air conditioning.

The more Rensair units in active use and circulation, the less energy is being used.

Circular economy

Circularity & Recycling

Our units are all built to the highest standards, with the aim to last a lifetime if properly serviced and maintained. The bulk of materials used to manufacture our products can be recycled.

Much of the unit – including the casing, motor and fan – is made from steel, which is infinitely recyclable. The fan unit contains a copper coil, which can also be recycled, avoiding landfill and slowing the depletion of natural resources. Another significant constituent material is rigid plastic, which is suitable both for closed loop (same product) and open loop (different product) recycling.

The air purifier’s HEPA filters are made from borosilicate fibreglass, housed within an aluminium casing. The filters can be treated as scrap metal and the fibreglass, rendered harmless by UVC disinfection, is simply burned off in the aluminium melting process. The UVC lamp bulb can be recycled like any other type of fluorescent bulb.

Rensair is currently working on establishing agreements with recycling organisations in key user countries, such that used consumables can be returned via pre-printed labels direct to appropriately qualified recycling stations, thereby ensuring that none end up in landfill.

We’ve even put together these handy maintenance tutorials to ensure everyone knows they work: How to maintain Rensair Devices