Deciphering the Paradox of CO2 Measurement in a building’s indoor air quality

Introduction

Post pandemic period has seen a number of studies and media articles that showed how Carbon dioxide (CO2) is an important indicator of a building’s Indoor Air Quality (IAQ). There was so much importance attached to its measurement that it caused a prolific increase in the number of CO2 sensors and monitors manufacturers in this unregulated IAQ market. But do CO2 levels in an indoor environment actually paint the correct picture of its IAQ?

The CO2 misnomer

For years, an indoor CO2 concentration below 1000 ppm has been deemed a benchmark for acceptable Indoor Air Quality (IAQ), yet often without a comprehensive understanding. This threshold primarily serves as an indicator of outdoor air ventilation per person. However, the use of CO2 as a ventilation indicator must acknowledge the variability in outdoor air ventilation needs based on factors such as space type, occupant density, and individual characteristics like age, body mass, and activity levels. Consequently, applying a uniform CO2 concentration across all space types and occupancies for ventilation rate assessment purposes is not suitable.

Also, in a Demand Controlled Ventilation (DCV) scenario, the amount of outdoor air brought inside changes depending on how many people are in the room and also on the CO2 levels outside.

While CO2 concentration may be one of the useful indicators of ventilation IAQ, there are other IAQ pollutants whose contribution to indoor pollution and airborne infection is significant. These include mould, viruses, Particulate Matter (PM2.5, PM4, PM10), aerosols, formaldehyde and other volatile organic compounds. With the increased outdoor air intake to maintain the traditional IAQ benchmark for CO2, we also bring in the outside polluted air that significantly raises the pollutant levels inside. Hence there is a need to monitor these pollutants and mitigate them to maintain a healthy indoor environment, not limited to CO2 measurement and adjustment.

ASHRAE’s Ventilation Standards

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) in their ventilation standards document ASHRAE 62.1 defined two methods (apart from natural ventilation) to design a building’s ventilation system.

- Ventilation Rate Procedure (VRP), where the outdoor air intake for a ventilation system depends on several factors like the room size, occupancy level and intended use of the space.

- Indoor Air Quality Procedure (IAQP), where the amount of clean air required to supply a healthy indoor environment requires periodic measurement of pollutants, particulate matter and other harmful volatile organic compounds in the air.

CO2 vs Ventilation methods

Measuring, or estimating concentrations of carbon dioxide indoors can be a good indicator of fresh air flow and provide a basis for a “rule of thumb”. However, CO2 alone cannot be used to determine indoor air quality. To properly determine indoor air quality additional measurements of concentrations of particulate matter and various volatile organic compounds are required.

ASHRAE’s Ventilation Rate Procedure (VRP) approach relies solely on these “rule of thumb” ventilation rates based on CO2 concentrations. As this procedure does not account for any other pollutants it must lean on the conservative side, often relying on over-ventilation as a safeguard, and assuming that outdoor air is clean. When we monitor indoor air quality we not only find that particulate matter and VOCs are not dependent on CO2, but also that the outdoor air quality has a large effect on these concentrations. In some cases simply over-ventilating a space to maintain CO2 concentrations can result in polluting the indoor air with poor outdoor air.

According to ASHRAE 62.1 [1], the required ventilation can be determined according to a procedure called Indoor Air Quality Procedure:

“ The IAQP is an alternative to the VRP used to determine the design rate of outdoor airflow to maintain concentrations of design compounds (DCs) and PM2.5 in the indoor environment to be less than design limits (DLs), based on indoor and outdoor sources, air cleaning, and other variables. These outdoor air requirements shall be calculated with mass-balance equations. ” – ASHRAE 62.1 – 6.1.2

Rensair’s Smart Demand Controlled Ventilation

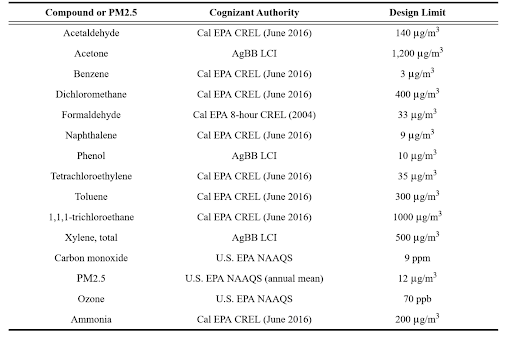

The table below shows the measurement capabilities required for qualification under the IAQP, along with the concentration limits for each compound.

Rensair’s air purification technology filters out these compounds using a combination of HEPA and carbon filters, while offering real time air quality monitoring to ensure ongoing compliance. Using the Rensair Cloud alarms and notifications can be set such that during pollution events fan speed is increased in the affected area to ensure that compounds do not exceed the design limits.

To ensure that there are no adverse effects from CO2, its levels are maintained below 1500 ppm, far below the maximum of 5000 ppm (maximum allowed CO2 level – OSHA Permissible Exposure Limit (PEL) & ACGIH Threshold Limit Value (TLV)). By applying this framework, air quality is kept high, cross-contamination risk is minimised, while energy consumption is optimised. In addition, our units will improve an individual’s perception of indoor air quality. Most individuals consider air quality poor when odours caused by VOCs are present, or there is a sudden change in the VOC levels. As CO2 is an odourless gas it is not a contributor, however the Rensair filtration system removes VOCs that contribute to perceived poor air quality.

Rensair SDCV vs any standard HVAC

Improving Air Quality in Polluted Urban Areas

Cities and rural regions near pollution sources like factories or farms often contend with outdoor air pollution. When outdoor air is brought indoors, these pollutants can enter buildings. Smart Demand Controlled Ventilation (SDCV) addresses this issue by first reducing outside air intake and employing enhanced filtration to eliminate harmful pollutants, thus improving indoor air quality. Additionally, to tackle the risk of cross-contamination, Rensair sensors detect increases in air pollutants from both indoor and outdoor sources, prompting increased fan speeds for rapid filtration of additional pollutants.

Energy Efficiency

Significant energy savings are achieved by reducing the volume of outside air conditioned by Air Handling Units (AHUs). Considering that ventilation systems typically consume 40% of a building’s energy, this reduction represents substantial energy savings.

Targeted Air Cleaning

Unlike central HVAC systems, which may struggle to detect local air quality variations and respond adequately, localised air filtration systems can swiftly address air quality issues in specific areas. This targeted approach prevents energy waste and ensures efficient delivery of clean air where it’s needed most.

Preparedness for Pandemics

Implementing SDCV significantly reduces the risk of cross-contamination from various pollutants, including viruses, ensuring a safer environment for building occupants. Rensair systems employ HEPA filtration to trap viruses and UV-light sanitation to eradicate viruses and bacteria, meeting the stringent guidelines set by recent ASHRAE standards for pandemic conditions. While central HVAC systems may struggle to meet these requirements without substantial upgrades, Rensair’s localised HEPA and UV filtration technology achieves an impressive 99% efficiency rate in delivering clean air.

CONCLUSION

In conclusion, while carbon dioxide (CO2) measurement has historically been regarded as a key metric for assessing indoor air quality (IAQ) and though CO2 levels can provide valuable insights into ventilation rates, they alone do not paint a complete picture of IAQ. The reliance on CO2 measurements for ventilation rates overlooks the diverse array of pollutants that can impact indoor air quality, including particulate matter, volatile organic compounds, and viruses.

Recognizing these limitations, organisations like ASHRAE have developed comprehensive ventilation standards that go beyond CO2 measurements to encompass a broader range of pollutants and factors influencing IAQ. Technologies such as Rensair’s Smart Demand Controlled Ventilation offer promising solutions by reducing outside air intake, employing enhanced filtration, and providing real-time monitoring to ensure optimal indoor air quality while mitigating energy consumption.

As we navigate the challenges of maintaining healthy indoor environments, it becomes increasingly clear that a multifaceted approach, considering various pollutants and ventilation strategies, is essential. By embracing such holistic approaches, we can create indoor spaces that prioritise occupant health, comfort, and safety in a post-pandemic world and beyond.